Update your processes to the digital era. Make your production system more efficient, identify weak points and anticipate failures before they occur. With Turck’s GEN-3G Ethernet gateway, you can transfer process information and meta data from the field to IT systems. There, intelligent condition monitoring algorithms transform this data into knowledge that helps you and your plant.

Digital Process Optimization for Hazardous Locations

Up to now, data has been distributed across many devices at the field level. Turck is paving the way for the evaluation of this data with its high-availability I/O system excom. Its GEN-3G Ethernet gateway provides an interface for parallel data access.

You can transfer process information and meta data from the field to IT systems where intelligent condition monitoring algorithms transform it into knowledge that helps you and your plant.

Tamper-proof data access

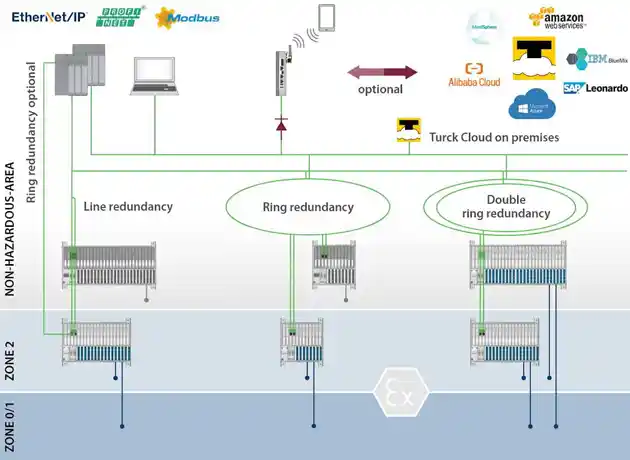

The excom Ethernet gateway is approved for installation in zone 2 Ex areas or in safe areas. It not only transmits usage data to the control system via multi-protocol Ethernet (PROFINET, EtherNet/IP, Modbus TCP). In addition to this user data, analysis data can be retrieved from the gateway by suitable network participants and transferred to outsourced IT systems.

These run in parallel over the same network. The IT system for data analysis has read authorization only. This prevents tampering with the process or control system. The systems for data analysis can be realized on premises without an external network connection or in cloud systems.

Full data access, maximum availability, absolute security

The graphic shows the variety of installation scenarios of excom with Ethernet. Combinations of different redundancy concepts increase the availability of the plant. The connection to asset management systems, mobile terminals and various clouds can be made via Turck’s encrypted cloud protocol Kolibri, OPC-UA or MQTT.

Thanks to parallel data access, the process data of the control system can be systematically separated from analysis data. In addition to the security aspect, this architecture offers a further advantage: In terms of monitoring and optimization (M+O), your plant benefits from the short innovation cycles of the IT world and can rely on the safety and reliability of OT (operational technology).

Parallel data access – fit for the future

The parallel data retrieval brings IIoT into the process world. Data is diverted into a parallel IT structure below control system level. This means that the control systems and process control remain untouched.

Outside the control and ERP systems, this data can be used to make valuable findings regarding component efficiency and failure probability. For example, if the running time of a valve connection increases, it may indicate corrosion or deposits. The findings from these analyses flow back into the processes at operation management level in optimization cycles.

Keni një pyetje për ne?

Paraqisni pyetjet ose kërkesat tuaja në formularin e hyrjes dhe ne do t’ju kontaktojmë sa më shpejt të jetë e mundur.